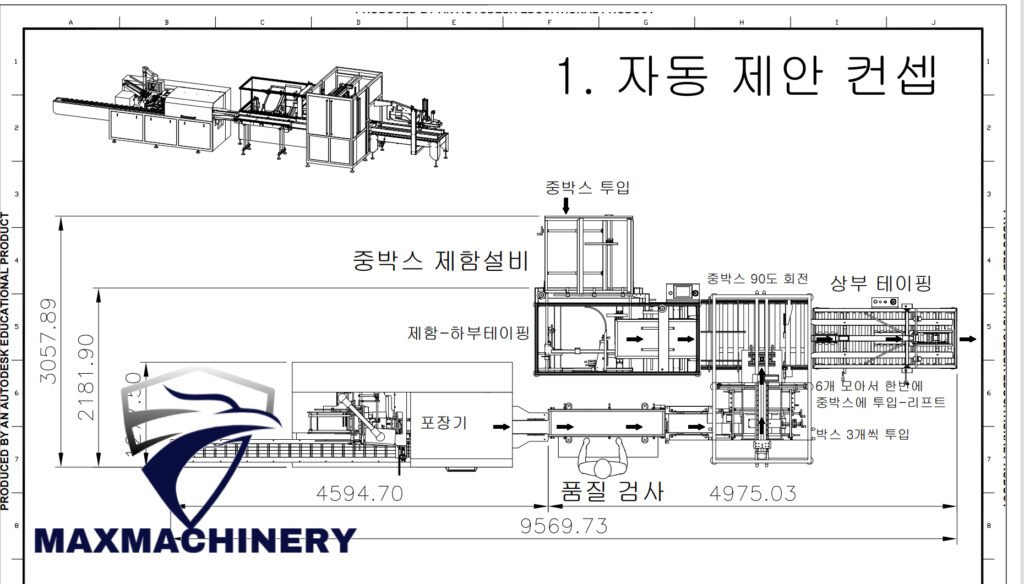

What is a case packer?

Maxmachinery series of fully automatic side-push Case packer line automatically packs boxed products. Cartons are tilted upside down from the machine, which automatically draws in and opens them. Stacked cartons are automatically pushed into horizontal cartons, and then sealed on both sides.

This machine is suitable for a variety of cartoned products and is primarily used in the daily chemical, pharmaceutical, and food industries.

Our fully automatic side-push cartoning line integrates a carton erector, case packer, and carton sealer.

Each cartoning line model can operate independently, offering flexible operation, low failure rates, and stable performance. This line is widely used in the pharmaceutical, food, and daily chemical industries. Its high level of automation significantly improves downstream packaging capacity, effectively boosting productivity, optimizing human resources, and reducing production costs. It is highly sought after by customers.

Machine Processing:

Our machine features a touchscreen control panel and a separate electrical box, allowing it to operate standalone or as part of a production line. It also includes an air conditioning unit to filter moisture and other impurities from the air, allowing for product stratification and grouping. After the first layer of stacking is completed, the stacking mechanism descends one level to stack the next layer of products. When three layers of products are stacked, the stacking mechanism ascends to the boxing position. Products are ready for boxing: The roller conveyor delivers the cartons opened by the carton opener to the boxing position. The sensor detects the carton, and the PLC controls the cylinder at the bottom of the carton to activate and push the carton into the boxing position. The carton’s side opening automatically opens and positions the carton. The side pusher pushes the product into the carton and pushes the carton containing the product back onto the roller conveyor. The side pusher pushes it back, and the next group of products are ready for boxing. The product boxing is complete.

This highly efficient system automatically pulls, unpacks, inverts, and seals cartons. Its flexible operation, low failure rate, and stable performance make it an ideal choice for the daily chemical, pharmaceutical, and food industries. This highly sought-after integrated packaging automation solution improves productivity, optimizes labor, and reduces costs.